Formwork vs Falsework: What’s the Difference?

Formwork vs Falsework: What’s the Difference?

Formwork and falsework are both temporary structures used in construction, but they serve distinct purposes.

Formwork is a mold that shapes and supports wet concrete until it hardens. It contains the concrete, ensuring it retains the desired dimensions and finish. Common materials for formwork include timber, steel, and plastic.

Falsework, on the other hand, provides temporary support to structures during construction until they can support themselves. It is essential for holding up formwork and can include props, frames, and scaffolding.

In the realm of construction, the terms formwork and falsework often come up, especially when dealing with large structures like bridges, high-rise buildings, and complex concrete projects.

While these two terms are frequently used interchangeably by those outside the construction industry, they refer to two distinct aspects of temporary construction structures.

Both are critical to the safe and efficient creation of permanent structures, but their roles, functions, and specifications differ significantly.

💥🎁 Christmas & Year-End Deals On Amazon !

Don't miss out on the best discounts and top-rated products available right now!

🛒 Shop Now and Save Big Today!*As an Amazon Associate, I earn from qualifying purchases.

Understanding the difference between formwork and falsework is essential for engineers, architects, and construction managers as these temporary systems provide crucial support during the building process.

This article aims to break down the distinctions, functions, and practices surrounding formwork and falsework to offer a clearer perspective on how these two terms are applied in construction.

What is Formwork in Construction?

Formwork is a temporary structure used in construction to shape and support freshly poured concrete until it hardens and gains sufficient strength to support its own weight.

The primary function of formwork is to mold concrete into the required shape and dimensions, ensuring the integrity of the structure. Once the concrete sets and gains its required strength, the formwork is removed or dismantled.

There are different types of formwork systems used in construction, each chosen based on the project’s specifications, complexity, and budget. These include:

- Traditional Timber Formwork: This method involves the use of wooden boards and supports. It is flexible but labor-intensive and is commonly used in smaller, less complex projects.

- Steel Formwork: Steel formwork is durable and reusable. It offers a smooth finish to the concrete surface and is commonly used in large projects where long-term cost efficiency is necessary.

- Plastic Formwork: Lightweight and modular, plastic formwork is easy to assemble and can be reused multiple times. It is ideal for projects with repetitive concrete shapes.

- Aluminum Formwork: Lighter than steel and equally reusable, aluminum formwork is often used in high-rise construction where speed and efficiency are critical.

What is Falsework in Construction?

Falsework, on the other hand, refers to the temporary structures used to support not only the formwork but also the weight of materials like concrete and steel until the structure is self-supporting.

💥🎁 Christmas & Year-End Deals On Amazon !

Don't miss out on the best discounts and top-rated products available right now!

🛒 Shop Now and Save Big Today!*As an Amazon Associate, I earn from qualifying purchases.

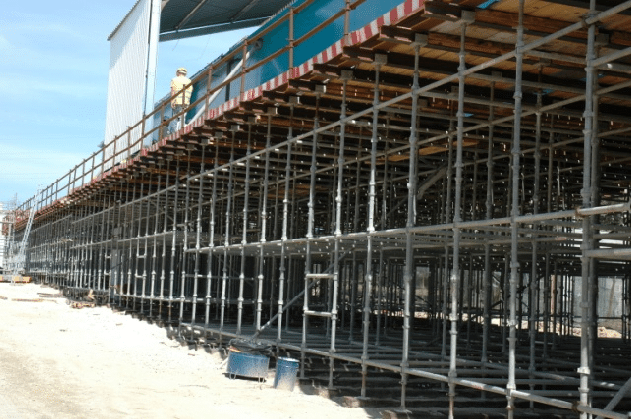

Falsework encompasses scaffolding, shoring, and other temporary supports designed to handle loads during construction. In essence, while formwork gives concrete its shape, falsework holds both the formwork and the structure in place.

Falsework can be composed of various materials such as steel, timber, or aluminum, depending on the design load and the project’s specific requirements. Falsework is critical in large-scale projects such as bridge construction, where the weight of the structure during its construction exceeds its ability to support itself.

Falsework vs Formwork: The Key Differences

While both formwork and falsework are crucial in construction, they serve different purposes, and understanding these differences is vital to ensuring safe and efficient construction practices.

- Primary Function: The main distinction lies in their purpose. Formwork is designed to mold and shape materials, primarily concrete, until they set, while falsework provides support to the formwork and the structure itself, ensuring that it remains stable during the construction phase.

- Duration of Use: Formwork is generally removed once the concrete has gained enough strength to support itself. Falsework, however, may stay in place longer, especially in large projects like bridges or towers, where it needs to support significant loads for extended periods.

- Materials Used: Both systems can be constructed from similar materials, such as timber, steel, or aluminum. However, falsework tends to use more robust materials due to the significant loads it supports.

- Structural Support: Falsework supports both the structure and the formwork, whereas formwork is primarily concerned with shaping the concrete. Without falsework, formwork, especially on large structures, would not remain stable during the construction process.

Are Formwork and Falsework the Same?

This is a common question among those new to the construction industry: Are formwork and falsework the same? The answer is a definitive no. While both are temporary structures used in construction, they perform very different functions.

As we’ve outlined, formwork shapes and contains concrete, whereas falsework supports both the formwork and the construction materials.

In simpler terms, formwork is responsible for the “shape” and falsework is responsible for the “support.” One could not exist without the other in most construction projects, as formwork without support could fail, and falsework without formwork would have no structure to support.

💥🎁 Christmas & Year-End Deals On Amazon !

Don't miss out on the best discounts and top-rated products available right now!

🛒 Shop Now and Save Big Today!*As an Amazon Associate, I earn from qualifying purchases.

System Formwork vs Conventional Formwork

In modern construction, there is a growing trend toward using system formwork, which consists of prefabricated, modular components that can be easily assembled and disassembled. System formwork is often contrasted with conventional formwork, which is custom-built on-site using materials like timber or plywood.

- System Formwork offers several advantages over conventional formwork, including faster assembly, improved safety, and greater precision. It is especially useful for repetitive tasks, such as building multiple floors in a high-rise building.

- Conventional Formwork, while more labor-intensive, can be customized to meet specific design requirements. This flexibility is invaluable in projects with complex geometries where pre-made systems might not fit perfectly.

Both system formwork and conventional formwork rely on falsework for support, but system formwork is usually more efficient, especially in large-scale projects.

Formwork and Falsework Code of Practice

When it comes to the construction industry, safety and efficiency are paramount. For that reason, both formwork and falsework are governed by a comprehensive set of regulations known as the formwork and falsework code of practice. These guidelines ensure that the design, erection, and dismantling of temporary structures meet the highest safety standards.

In many countries, including the UK and the US, these regulations are enforced through national codes, which outline specific requirements for load-bearing capacities, material quality, and worker safety.

For example, in the United States, OSHA (Occupational Safety and Health Administration) has strict guidelines that dictate how formwork and falsework systems should be constructed and maintained to avoid structural failures and accidents.

Compliance with these standards is not only a legal requirement but also a crucial aspect of project management, as failures in formwork or falsework can lead to costly delays, structural failures, or even fatal accidents.

💥🎁 Christmas & Year-End Deals On Amazon !

Don't miss out on the best discounts and top-rated products available right now!

🛒 Shop Now and Save Big Today!*As an Amazon Associate, I earn from qualifying purchases.

Formwork and Falsework Specifications

Both formworks and falseworks have detailed specifications that must be followed to ensure they perform their intended roles safely and effectively. The specifications typically include:

- Load-bearing capacity: Both systems must be designed to support the weight of wet concrete and any additional loads, including workers and machinery.

- Durability: Materials used in formwork and falsework need to withstand the conditions of the construction site, such as exposure to weather, water, and chemicals.

- Assembly and disassembly: Both systems must be easy to erect and dismantle while ensuring worker safety.

Importance of Falsework in Construction?

In construction, falsework plays a crucial role in providing the temporary support that a structure needs before it is self-supporting. Falsework is especially important in large-scale construction projects such as bridges, tunnels, and high-rise buildings.

Without falsework, the formwork would not be able to maintain its shape and integrity, leading to potential collapse during the pouring of concrete or the assembly of other materials.

Falsework is composed of scaffolding, braces, shores, and other temporary structures that bear the weight of both the permanent structure and the formwork. These systems are engineered to distribute loads evenly and prevent movement or shifting during construction.

Forms and False Works in Bridge Construction

Bridge construction often provides a clear example of the interplay between forms and false works. In such projects, falsework is essential to supporting long spans of concrete or steel before they are self-supporting. The formwork in these cases shapes the concrete girders or supports, while the falsework ensures the stability of the entire structure during the building process.

Without falsework, the formwork used in bridge construction would collapse under the weight of the wet concrete or steel beams. As a result, engineers meticulously calculate the loads and forces involved in designing falseworks and formworks to ensure the safety and success of the project.

💥🎁 Christmas & Year-End Deals On Amazon !

Don't miss out on the best discounts and top-rated products available right now!

🛒 Shop Now and Save Big Today!*As an Amazon Associate, I earn from qualifying purchases.

Formwork and Falsework Computation

Formworks and falseworks computation refers to the calculations and design processes required to ensure that both systems can handle the loads they are subjected to during construction. Engineers must consider factors such as the weight of the wet concrete, the pressure exerted by the concrete during pouring, and environmental factors like wind and rain.

For example, in high-rise construction, the computation of falsework ensures that the scaffolding and support structures can bear the weight of multiple stories of concrete or steel as they are constructed. Similarly, the computation of formwork ensures that the molds and shapes used to cast concrete do not deform or collapse under the pressure.

Conclusion

In the construction industry, both formwork and falsework are indispensable. While formwork molds and shapes the concrete, falsework supports both the formwork and the structure itself until it is stable. Understanding the difference between formwork and falsework is critical for engineers, architects, and construction professionals, as these temporary structures ensure the safety and success of complex projects.

Whether you’re dealing with system formwork vs conventional formwork or large-scale falsework computations for a bridge, these systems must be designed and implemented with care. Complying with formwork and falsework codes of practice ensures not only the integrity of the structure but also the safety of everyone involved in the construction process.